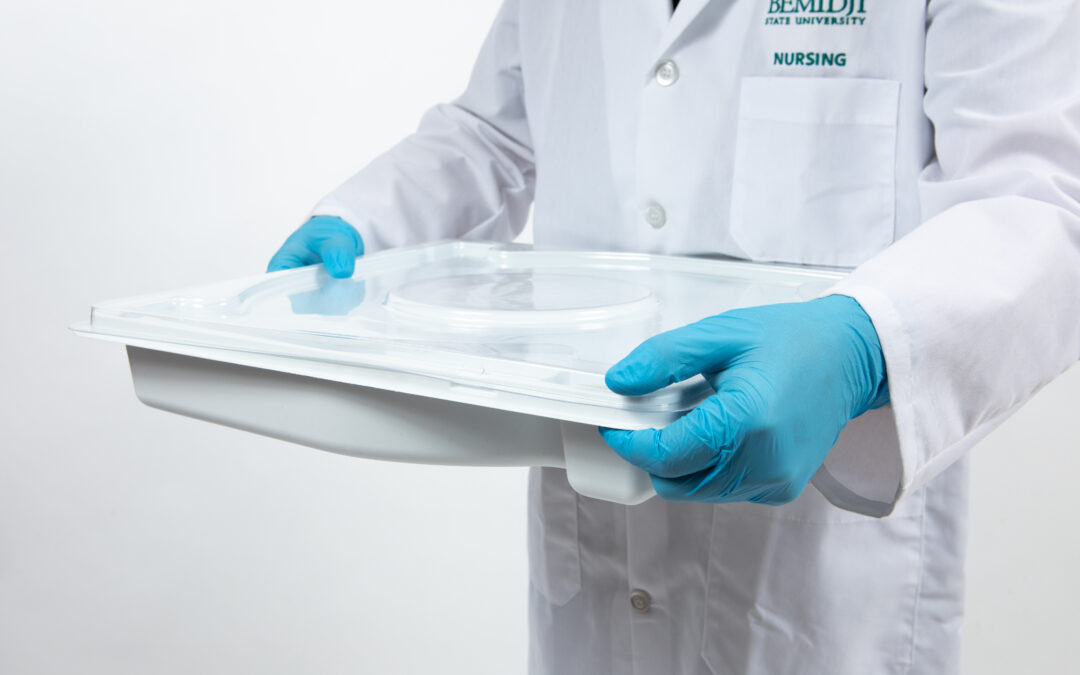

When material selection means choosing between thermoplastic products or metals, it’s important to select the right material type and process; the one that performs best for the application, while also being the most cost effective. This is also true when comparing thermoforming to injection molding and rotomolding.

Thermoplastic is made from different types of materials (sheets, pellets, resins), and includes thermoplastic elastomers (TPE), or thermoplastic rubber (TPR), and thermoplastic polyolefin (TPO). Finishes, colors, or thicknesses also vary. See our earlier blogs on TPR and TPO for more on each one’s benefits, differences, and applications. The main advantages in using TPR are flexibility and the ability to hold its shape, due to its characteristics and rubber-like performance. When considering TPOs, benefits include high-impact strength and the way it holds its shape and dimensions.

TPO is advantageous in applications where salt corrosion can degrade metal. Commercial examples include over-the-road hauling with semi-trucks or with terminal tractors at a shipyard. Some metal fabricators are even turning to plastic components for vehicle exteriors to avoid the effects of salt damage.

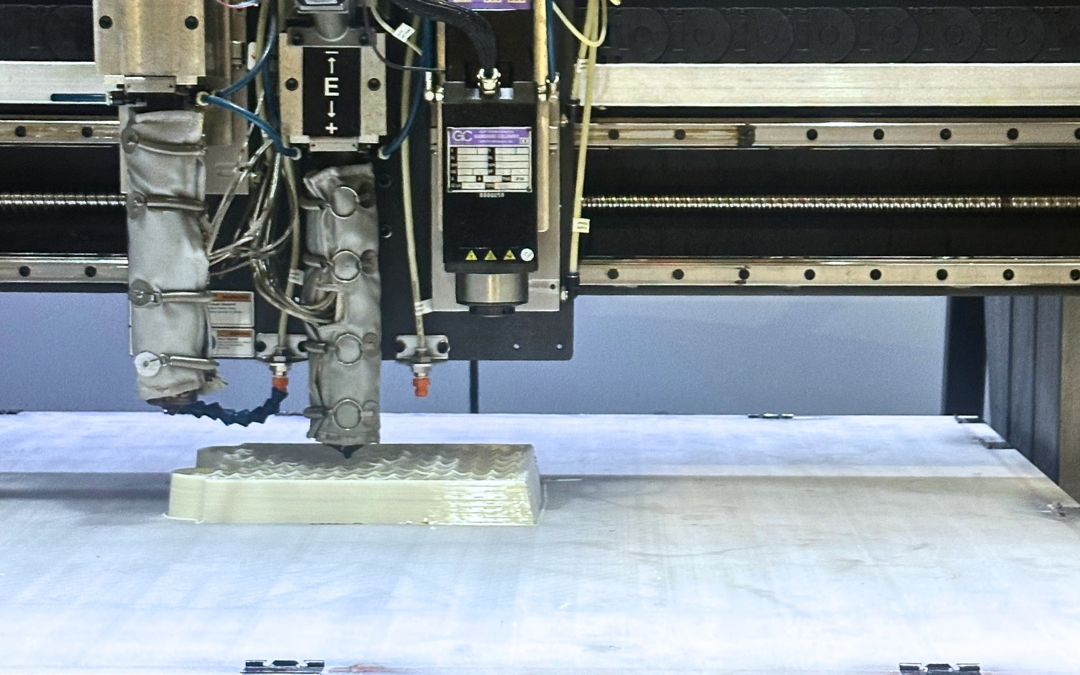

When choosing among thermoforming, injection molding, or rotomolding, research the basics of the different processes, applications, costs, and lead times. For example, costs of thermoforming are less expensive, especially as the size of a part increases, and thermoforming can handle run sizes from medium to large. (See chart on this page for comparisons.) Components made with TPO are less expensive than their metal counterparts, leading to a lower overall cost. The size of a part or the volume needed also affects the decision.

As experts in custom thermoforming, we are able to customize any plastic material your project may require. Our innovation and processing ability set LINDAR apart from other thermoforming companies. See for yourself. Contact LINDAR to learn more about material comparisons or to discuss what type of material would be the most effective for your application.