If you’re an OEM, you’ve undoubtedly heard of custom thermoforming—but are you familiar with its many benefits specific to the creation of OEM components? Now more than ever, OEMs are looking to custom thermoforming’s value-add process to create high-performance plastic components for their products.

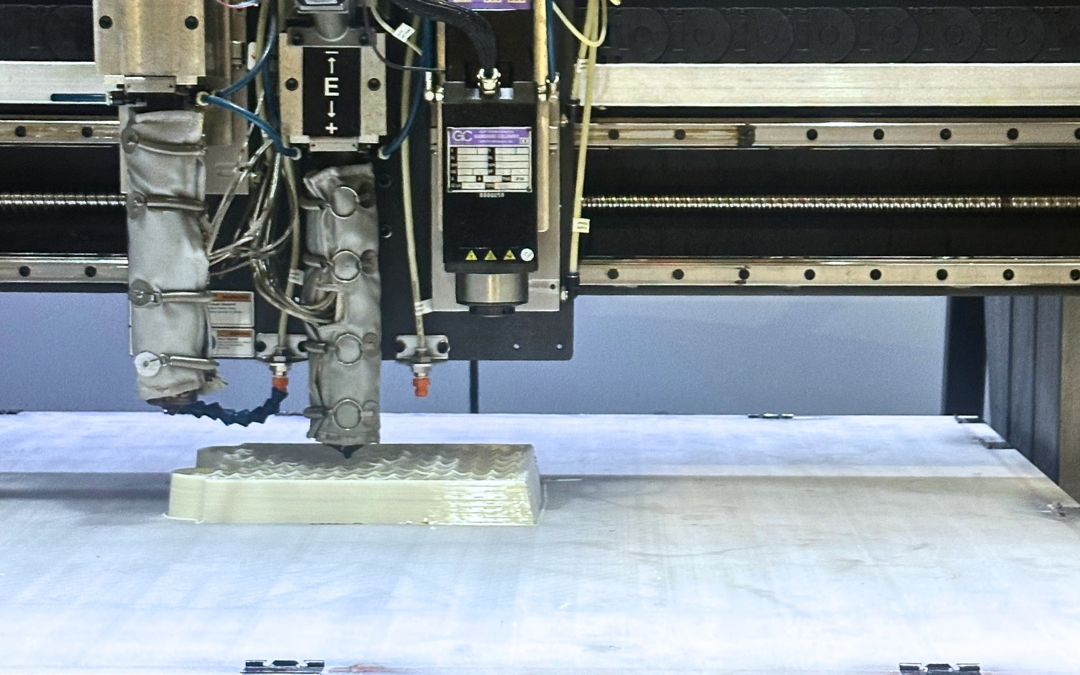

While thermoforming has experienced a major boost in popularity in recent years (with innovative technology developments to match,) it is by no means a new process. Thermoforming has been used by manufacturers for over 90 years to achieve an ideal balance of durability, weight, aesthetics and cost. With time-tested processes and state-of-the-art tech, custom thermoforming provides a value-add solution to modern challenges like the rising prices of oil and steel, long lead times, and the sheer overall cost of doing business in the 21st century.

In this blog, we’ll dive deeper into these significant benefits of custom thermoforming for OEM components and others, touching on how LINDAR leverages these elements to our clients’ advantage along the way. Read on to learn how custom thermoforming your OEM components can lead to cost savings, increased product performance, a greener footprint, and more!

Benefits of Custom Thermoforming OEM Components

Here’s a quick run-down of the many benefits of custom thermoforming OEM components. We’ll talk about each benefit listed here in greater detail below:

Cost-Effective Custom Thermoforming

Talk about bang for your buck: Custom thermoforming is a cost-effective manufacturing process, especially for low- to medium-volume production runs. The cost-savings and efficiencies of custom thermoforming come down to three main features: The process, the materials, and the efficiency.

Process: The thermoforming process requires a relatively low level of pressure to form the components, so thermoforming tooling construction is less costly than the tooling used in other manufacturing processes. The same is true for permanent molds and prototypes, both of which are less expensive in thermoforming than processes like injection or sheet molding.

Materials: Plastics offer significant cost-savings in comparison to other materials, especially when you factor in today’s rising costs of resources like steel and fuel. Additionally, plastic has remarkable longevity, even in harsh environments and conditions—it does not rust, it is not brittle, and it lends itself well to value-add coatings. These features reduce the likelihood that the user of the finished OEM product will need to make costly replacements of the component down the line.

Efficiency: OEMs know that time is money, and custom thermoforming is a quicker, more efficient manufacturing process compared to others. This makes custom thermoforming an attractive option for manufacturers looking for budget- and timeline-friendly options for their OEM components.

Customization for OEM Components

As the name suggests, custom thermoforming allows for the creation of highly-customized OEM components tailored specifically to the needs of a particular product or application. The LINDAR team is highly experienced in manufacturing OEM components, and we’ve found that our custom thermoforming process leads to better performance in the final product and increased efficiency across the board. By listening carefully to our OEM clients’ needs for all facets of their project—from the fundamental function and performance of the OEM components to the budget, timeline, volume and beyond—we can make expert recommendations that optimize the manufacturing process, the components, and the clients’ final products.

Durable OEM Components

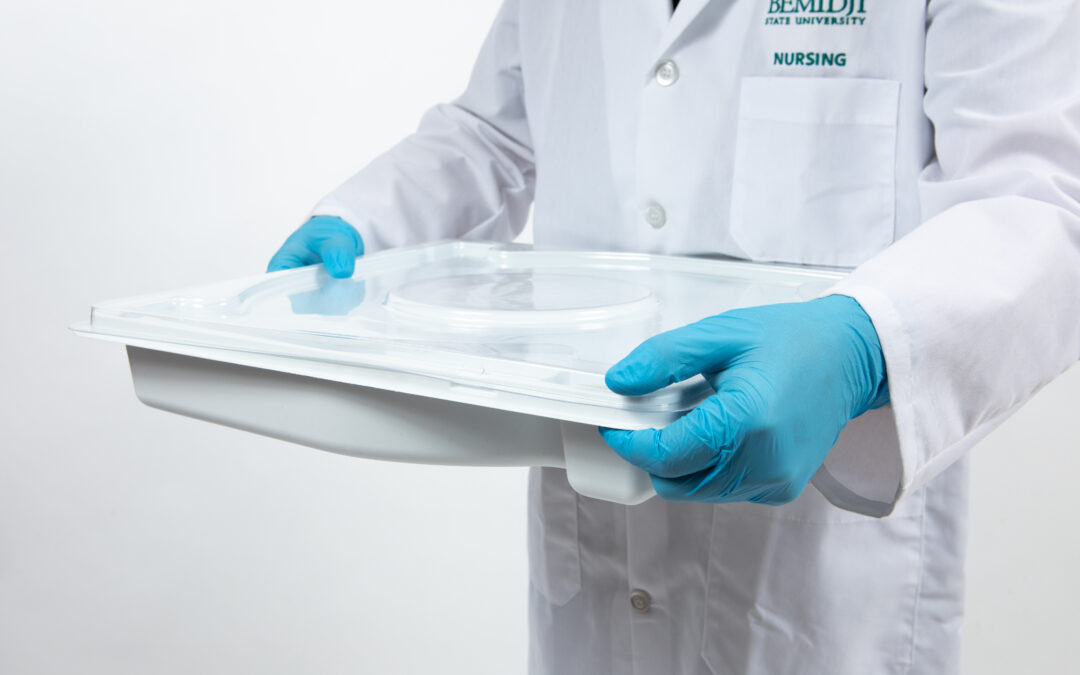

Thermoformed components are highly durable and resistant to wear and tear, making them suitable for use in demanding applications. They are also less susceptible to damage from impact or exposure to harsh environments, so thermoformed components are often ideal for use in outdoor environments. At LINDAR, we’ve custom thermoformed OEM components for use in agriculture, construction, landscaping, and powersports, all to great effect. We offer value-add capabilities as part of our custom thermoforming process, like the use of UV-protected, high-impact plastics, that increase the overall longevity of both the components and the final product.

Lightweight OEM Components

Thermoformed components are generally quite lightweight, making them ideal for use in OEM products that require portability and ease of handling. In turn, custom thermoforming clients benefit from lower shipping costs and reduced fuel consumption, providing additional cost-saving benefits.

Sustainable Custom Thermoforming

So custom thermoforming is innovative, budget-friendly and cost-effective—but did you know it’s also an eco-friendly manufacturing method? It’s true: Custom thermoforming is a sustainable manufacturing process that generates less waste compared to other plastics manufacturing methods. It allows for the use of recyclable materials like PET, the world’s most-recycled plastic, and other recyclable plastic materials, ultimately reducing the overall environmental impact of the production process.

LINDAR uses recyclable materials in the vast majority of our custom thermoforming solutions, like ABS, PS (polystyrene), polycarbonate, TPO and others. We also regularly custom thermoform OEM components using a variety of PET blends, including:

- APET

- RPET

- Post-consumer PET

Recyclable plastics vs. petroleum-based plastics have very few differences when it comes to performance elements like durability, so we strive to use recyclable plastic materials and blends in our custom thermoforming for OEM components whenever possible and appropriate for the application.

Versatile Manufacturing Process

Thermoforming is an exceedingly versatile manufacturing process, and can therefore be used to manufacture a wide range of OEM components with ease. From small parts to large panels, the sky’s the limit on custom thermoforming’s capabilities, and the process’s versatility makes it easier to pivot in the case of changes to a component’s design, material choice, etc. than in other manufacturing methods.

Speaking of material choices: The custom thermoforming process is compatible with an equally expansive variety of plastic materials, thicknesses, coatings, and more. LINDAR works with ABS, TPO, HIPS, PE, PETG, PC and many others in our custom thermoforming for manufacturers.

Although many OEMs are familiar with the types of plastics commonly used in custom thermoforming, the LINDAR team is happy to walk clients through their options after listening to their unique needs and specifications for the application of the component. The versatility of our custom thermoforming process and materials means there are many potential solutions to whatever problem or challenge is presented by an application or design, so requesting a consultation with our expert team is the best way to determine the right material for your project!

Looking for a Custom OEM Components Manufacturer?

LINDAR is a custom plastics thermoforming manufacturer of OEM components with the capabilities and expertise to meet your needs. The OEM components we produce are precisely manufactured, highly efficient, and backed by our commitment to innovation, cutting-edge technology, and exceptional customer service. Contact us today to tell us more about your OEM product and its component needs. Together, we can form something amazing.