BAXTER, MINN. — LINDAR Corporation, a leading manufacturer of thermoformed OEM parts for equipment, machinery and vehicles of all types and sizes, has expanded its Baxter, Minn., facility and its OEM manufacturing capabilities.

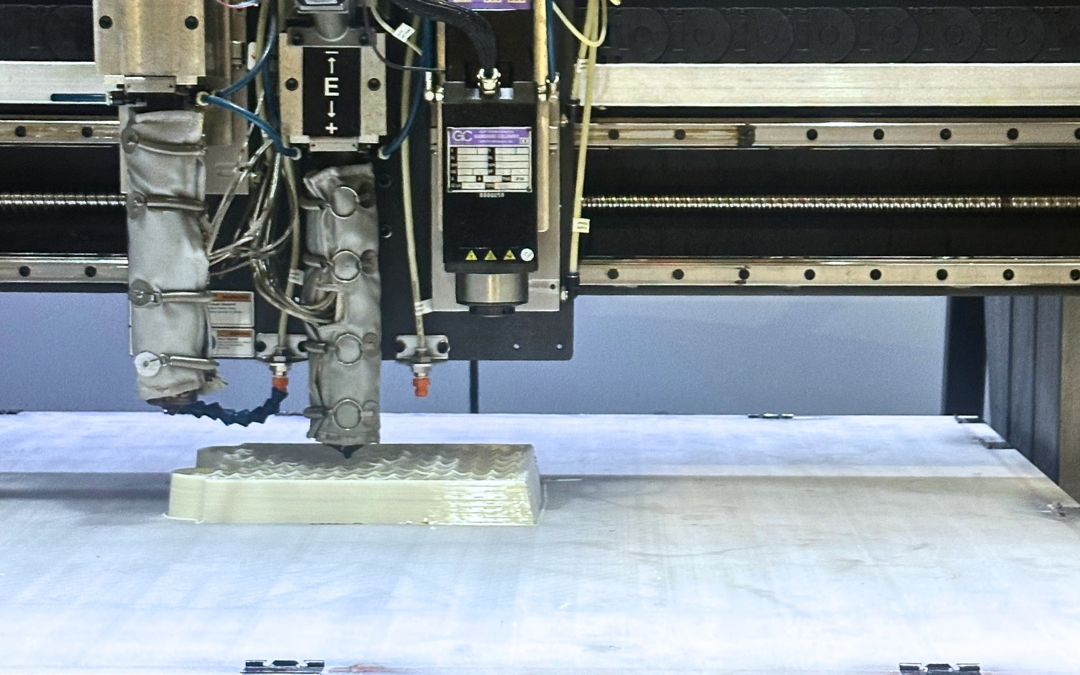

LINDAR recently completed a 33,000-square-foot building expansion, in part to house a new MAAC three station rotary machine that was purchased to advance LINDAR’s production efficiencies and product offerings.

“This machine gives us the ability to process higher quality products while improving efficiencies,” said Gordy Murphy, LINDAR’s operations manager.

Purchased for its speed and accuracy, LINDAR’s three station rotary thermoforming machine can handle extra-large sheets of plastic and molds up to eight-feet by six-feet in size.

“The additional capacity this machine provides will accommodate our customers’ growth and added capacity requirements,” Murphy said. “It’s advanced technology with advanced capabilities and it allows us to bring some of the newest product concepts and manufacturing methods to life.”

The three station rotary machine allows LINDAR to form larger parts and components while increasing manufacturing speed and reducing energy consumption.

“This is a significant investment in the future of LINDAR,” said Dave Fosse, LINDAR’s director of marketing. “Our building expansion, the new equipment, and our added thermoforming capabilities are a testament to the overall growth LINDAR is experiencing as a company.”

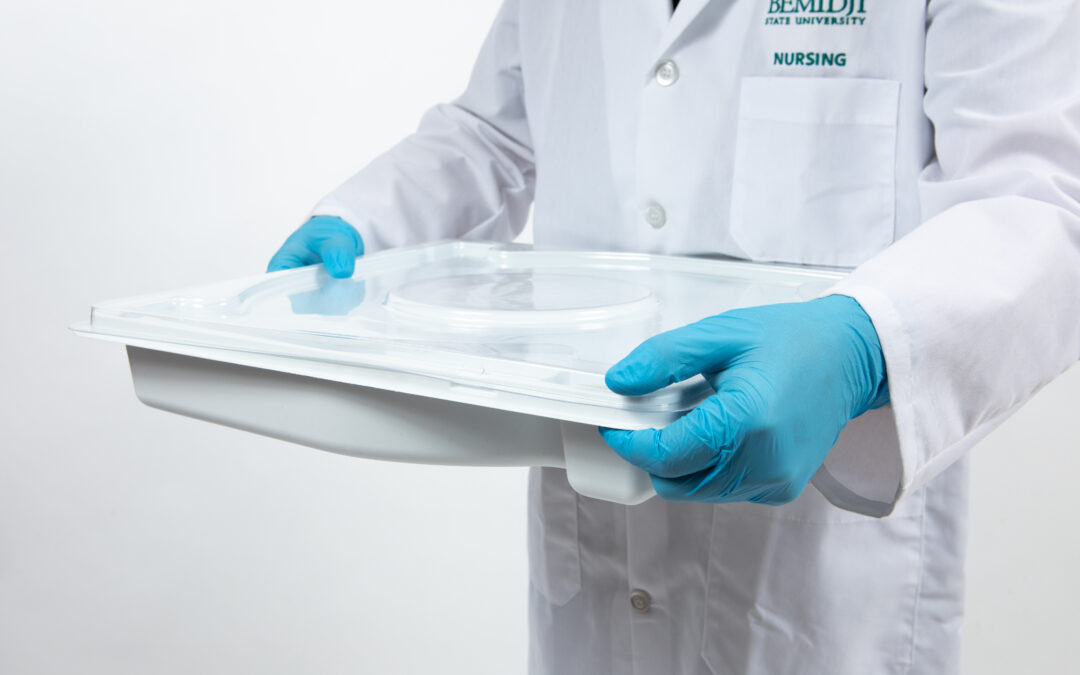

Based in Baxter, Minn., LINDAR specializes in thermoforming large parts for agricultural and lawn care equipment, recreational vehicles, construction and industrial machinery, as well as medical equipment for customers across North America. For more information, visit www.LindarCorp.com/oem-products.