Stephen Mraz

Thu, 2013-08-29 09:09

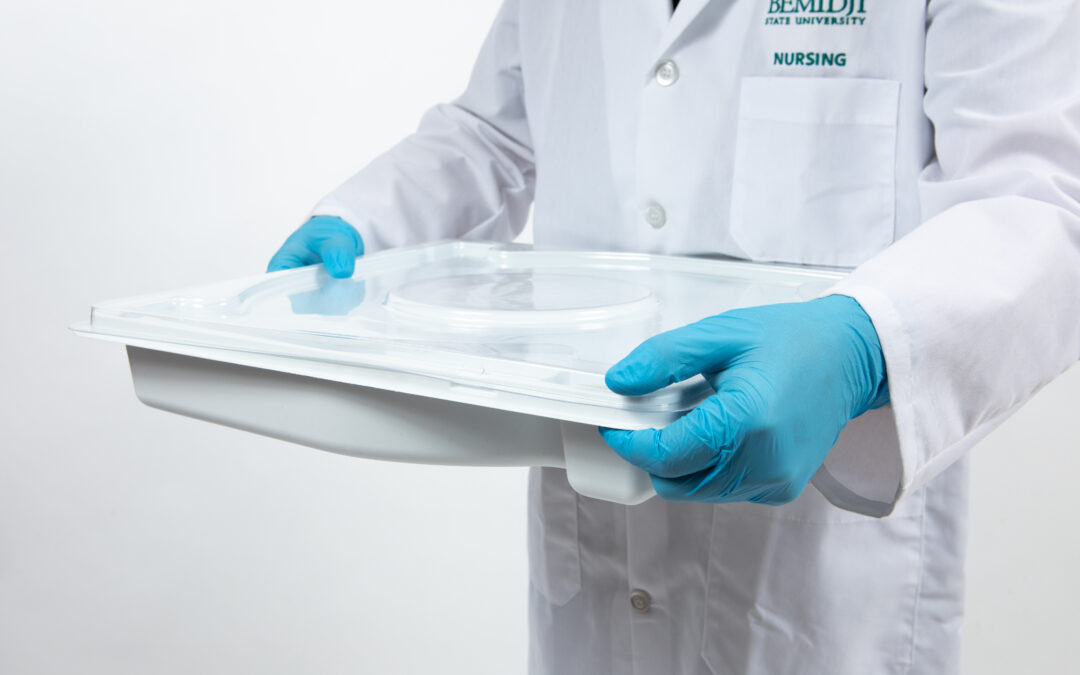

Customers of Lindar Corp., a plastics thermoformer in Minnesota, often want functional prototypes of food containers to test and evaluate. And they want them in only a couple of days. This hasmeant Lindar has had to develop tooling and thermaform containers, often with hinged lids, in a matter of days. To speed this process, engineers at Lindar explored 3D printing with selective laser sintering. The resulting mold prototypes proved to be too brittle because of the material used in the sintering process.

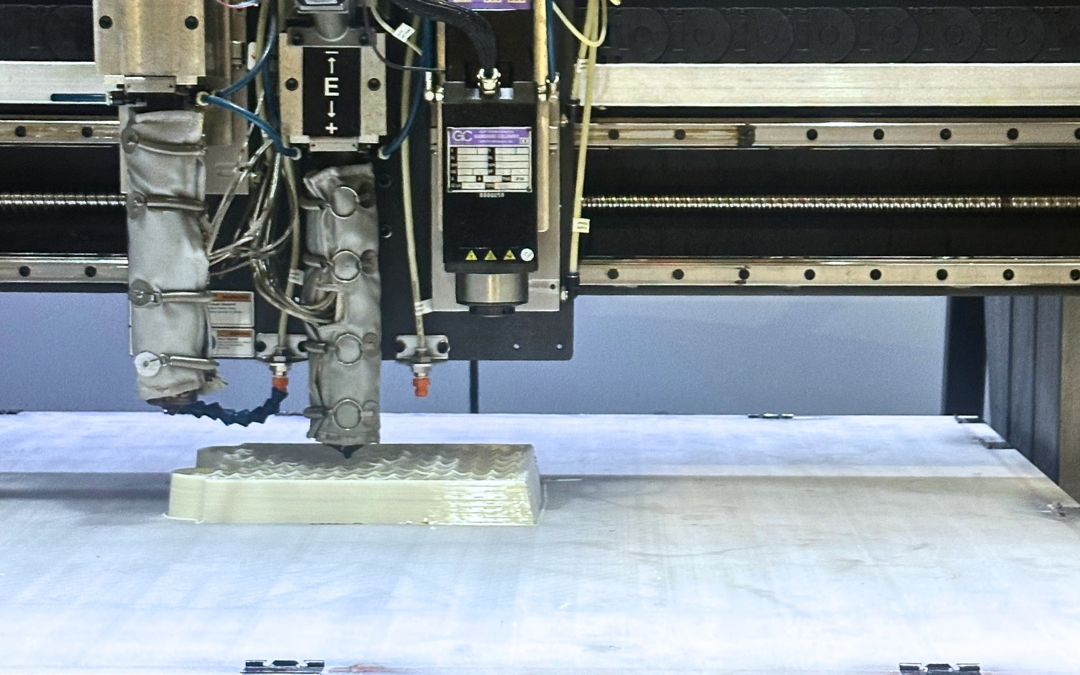

RedEye, Eden Prairie, Minn., then tried its hand at making the molds using fused-deposition modeling. Its technology, together with production-grade thermoplastics and lots of experience building molds for packaging devices with hinges, let RedEye quickly build working prototypes. Packaging made from the custom tooling can be used to evaluate fit and general appearance, and are durable enough to withstand physical and environmental testing.

Another advantage of the 3D-printed molding tools is that they are made of inherently porous plastic. Vacuum-forming machines can pull a vacuum through them to create parts. This eliminates the need to design and drill vacuum holes or vents in the tool. Deciding how many holes and where to put them is a tricky process, and doing it wrong can degrade the quality of the final part. The RedEye tool needed no vent holes but could still produce fine details on the thermoformed part.

Lindar now uses Red Eye to cut thermoforming prototyping times by as much as 60%.

Source URL: https://machinedesign.com/3d-printing/3d-printing-makes-tools-quickly-vacuumforming