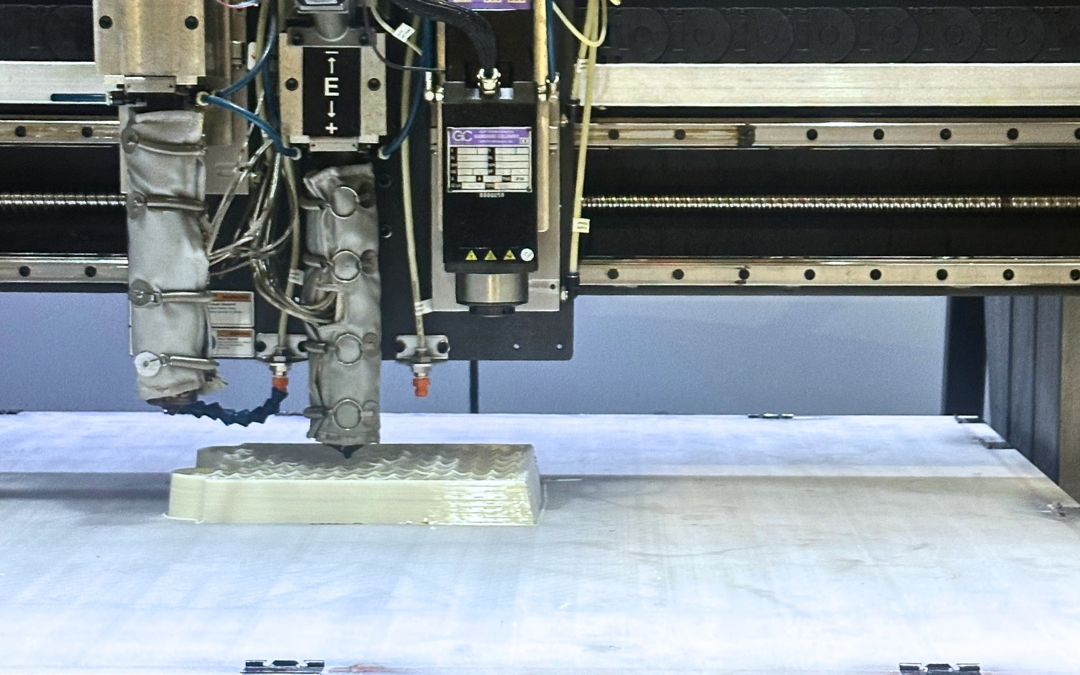

LINDAR recently invested in an HP Jet fusion 540 3D printer—another advancement in technology that reveals our dedication to making faster product development a priority for all our customers.

By making 3D printed molds and parts directly from a digital file, this reduces time from traditional development processes. This 3D printer technology will allow us a faster product development process from design, prototype to production—reducing the time to market across our custom parts, paint products and food packaging.

Features of the 3D printer include:

- Direct from design software to printing parts

- Improved prototype turnaround

- Future-ready technology

Among other applications, we will use the 3D printer for prototype molds and plugs, check fixtures, and assembly fixtures. A check fixture is to verify that holes or brackets are the correct size and in the correct place on formed part. An assembly fixture holds the parts in place for our team to assemble the parts into on assembled part.

Our investment in the technology of the 3D printer is another example of how we are increasing the value and offering ongoing improvement as we continue forming inspiration for our customers.